Circulation pumps in heat pump boiler sets and gas boilers play a vital role, as they are responsible for driving the thermal medium through the system for heat transfer and distribution.

1.Heat pump boiler group circulation pump

The circulating pump in the heat pump boiler set is mainly used to push the heat medium (such as water or refrigerant) circulating flow in the heat pump system. Its working principle is to drive the impeller inside the pump body to rotate through the motor, thereby generating centrifugal force, the heat medium from the lower part of the inhalation and pushed to the high or distant place. In the heat pump boiler group, the performance and selection of the circulating pump directly affects the operating efficiency and energy consumption of the system.

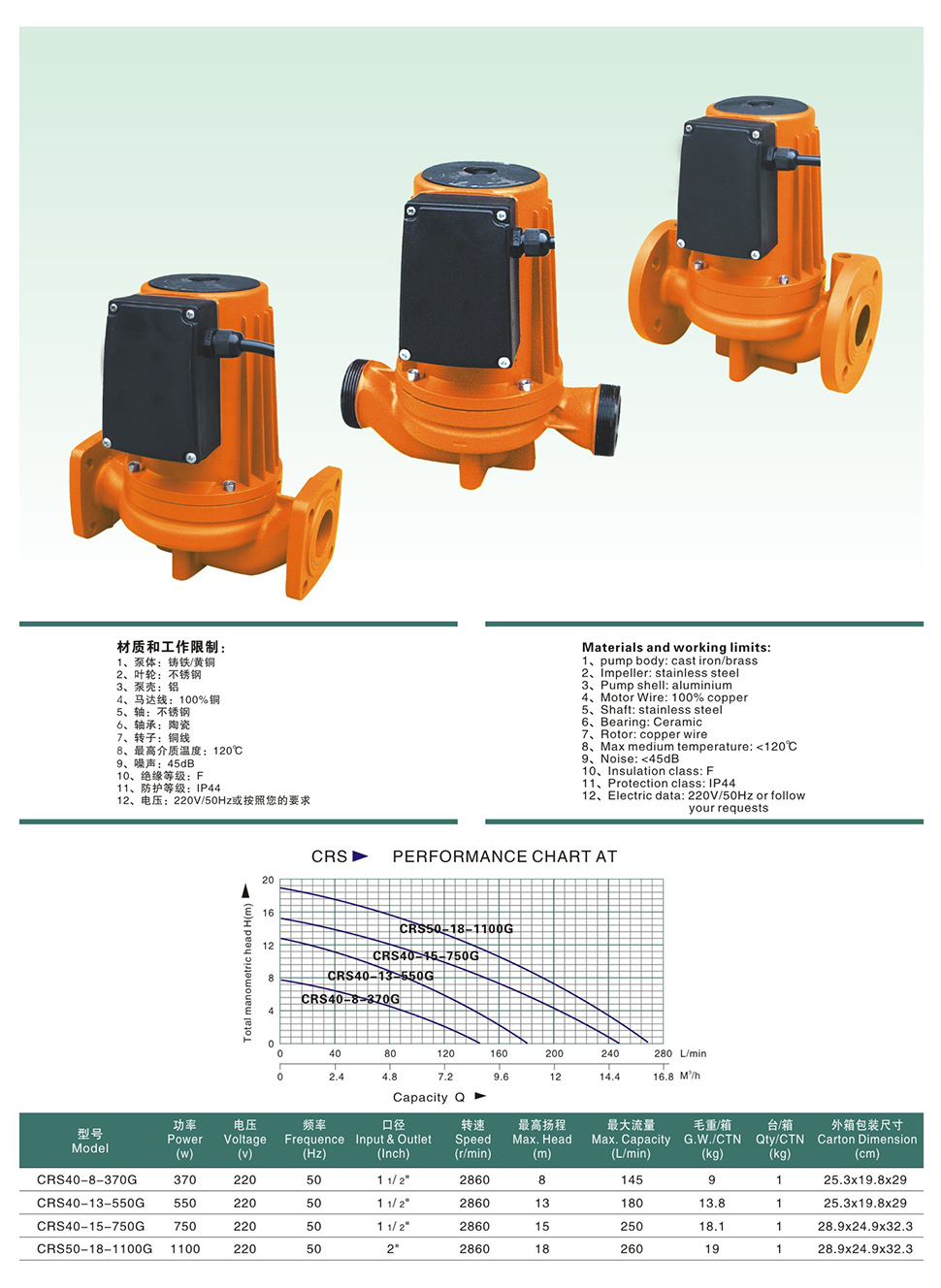

Performance characteristics: circulating pumps in heat pump boiler sets are usually characterized by high efficiency, energy saving and low noise. They can adapt to different working conditions, such as temperature, pressure, flow, etc., and can maintain stable operation under these conditions.

Selection principle: When selecting circulating pumps for heat pump boiler sets, the specific needs of the system need to be considered, such as the type of heat medium, flow rate, head and so on. At the same time, it is also necessary to consider the performance parameters of the pump, such as efficiency, power, speed and so on. In addition, the pump brand, quality, after-sales service and other factors are also important factors to consider when selecting the type of

2. Gas boiler circulating pump

Circulation pumps in gas boilers are mainly used to promote the boiler water or heat media in the boiler and heating system between the circulation flow. Their role is to transfer the heat generated by the boiler to the heating system, thus realizing the purpose of heating.

Working Principle: The working principle of gas boiler circulating pump is similar to that of heat pump boiler set circulating pump, which is to generate centrifugal force by driving the impeller inside the pump body to rotate through the electric motor, so as to push the heat medium to circulate and flow.

Performance characteristics: gas boiler circulating pumps are usually characterized by high temperature resistance, corrosion resistance, wear resistance and so on. They are able to operate stably in high temperature, high pressure and other severe working conditions, and maintain good performance.

Selection principle: When selecting gas boiler circulating pumps, you need to consider the boiler model, capacity, type of heat medium and flow rate and other factors. At the same time, it is also necessary to consider the performance parameters of the pump and the working environment conditions. Selection should ensure that the pump can meet the needs of the system and minimize energy consumption and noise while ensuring performance.